High Quality Steel Products

Long Products

We offer very competitive pricing for long products such as wire rod, re-bar, and billets. With our products you can rest easy that you will get the right material whether its for manufacturing nails, binding wire, or even welding electrodes.Learn More

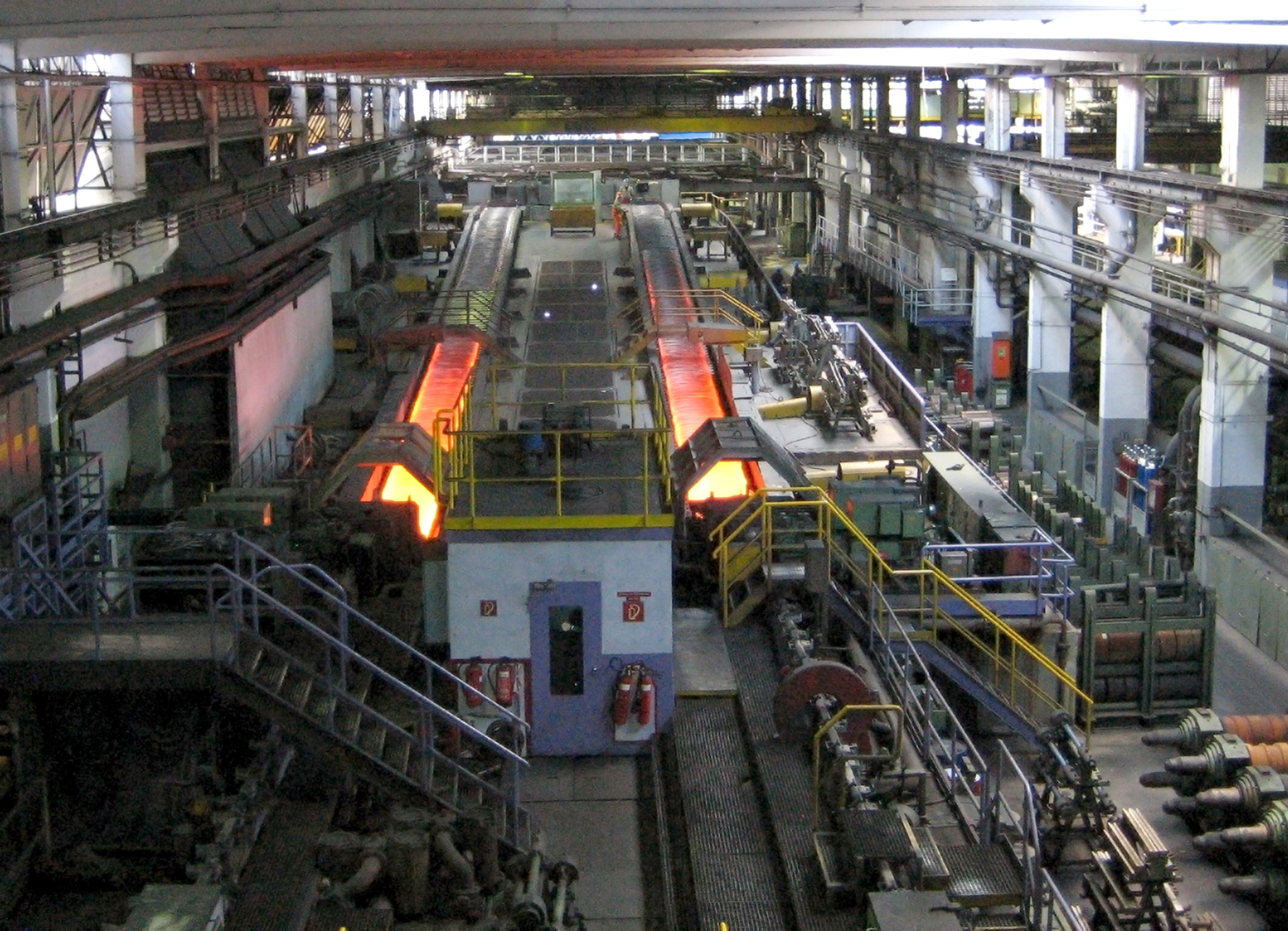

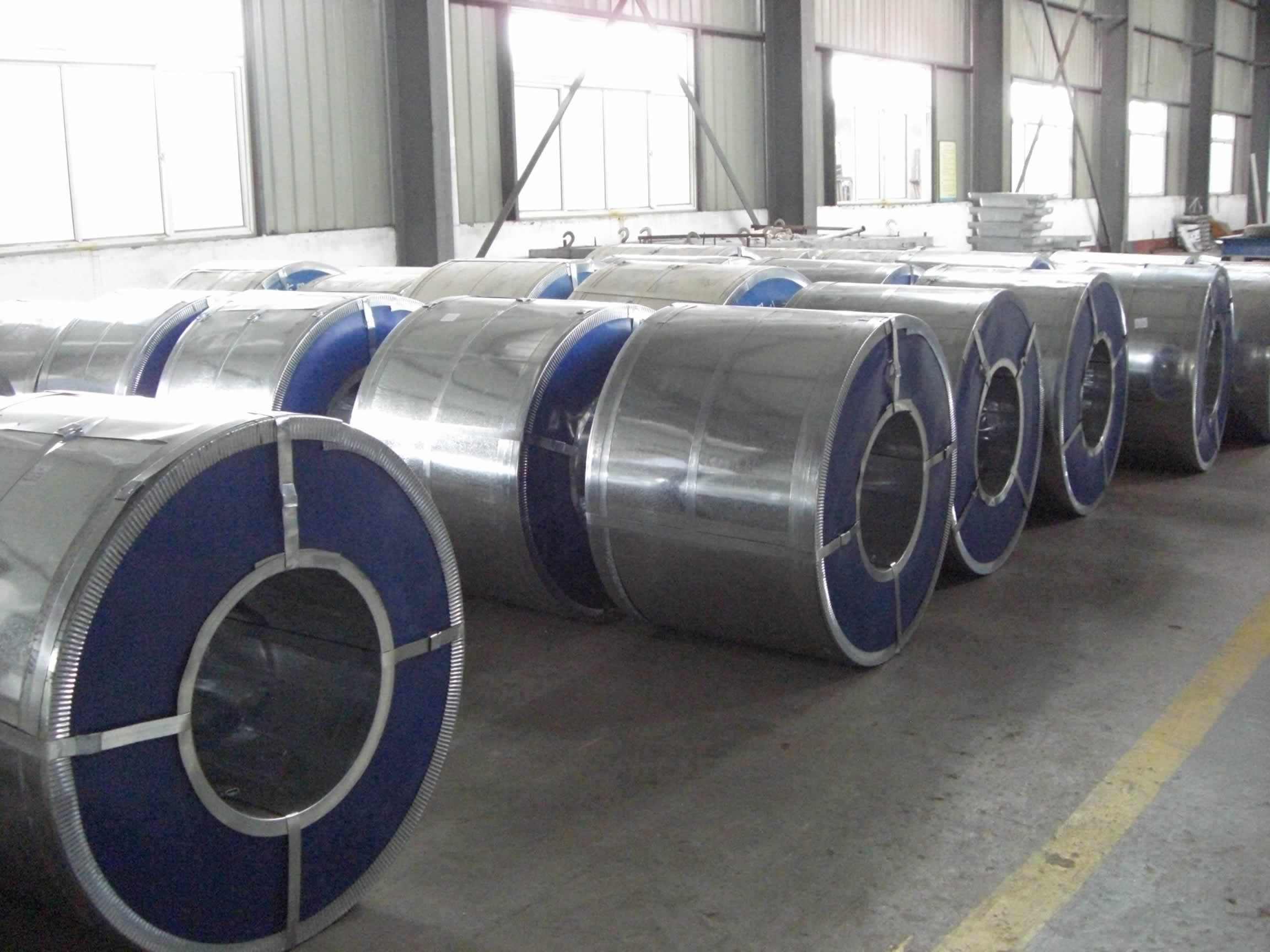

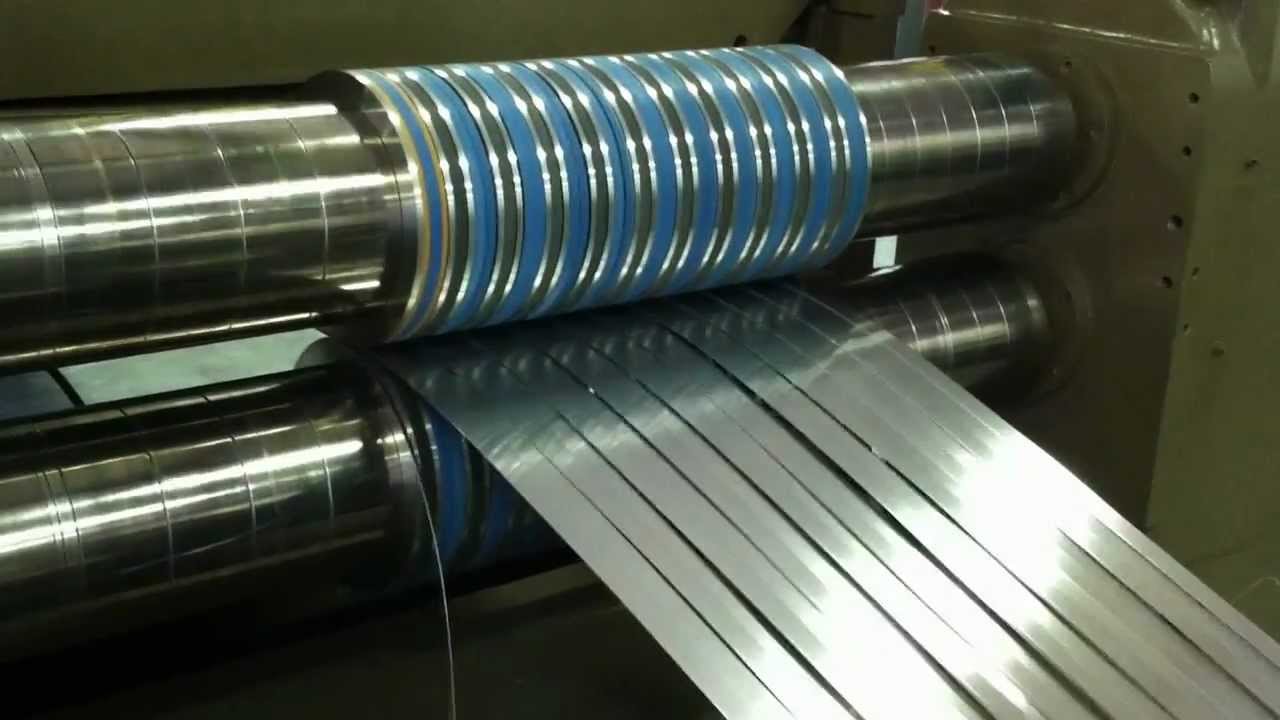

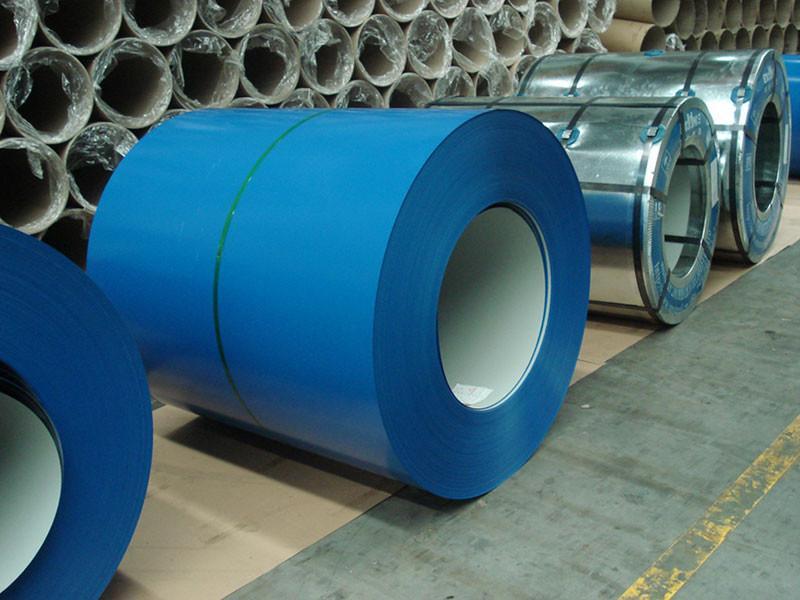

Flat Products

We offer a broad range of flat products such as CRC Coils, HRC Coils, PPGI, PPGL (Galvalume / Aluzinc) Coils which are widely used by our client in the roofing and cladding business.Learn More

Steel Pipes & Fittings

We offer all kind of Steel pipes made of Carbon Steel, Duplex, Super Duplex, Inconel, Titanium, and other Exotic Materials based on your requirements. We can also source Gaskets, Fittings, Flanges, Fasteners etc as per your specifications..Learn More